Allevamento in batteria

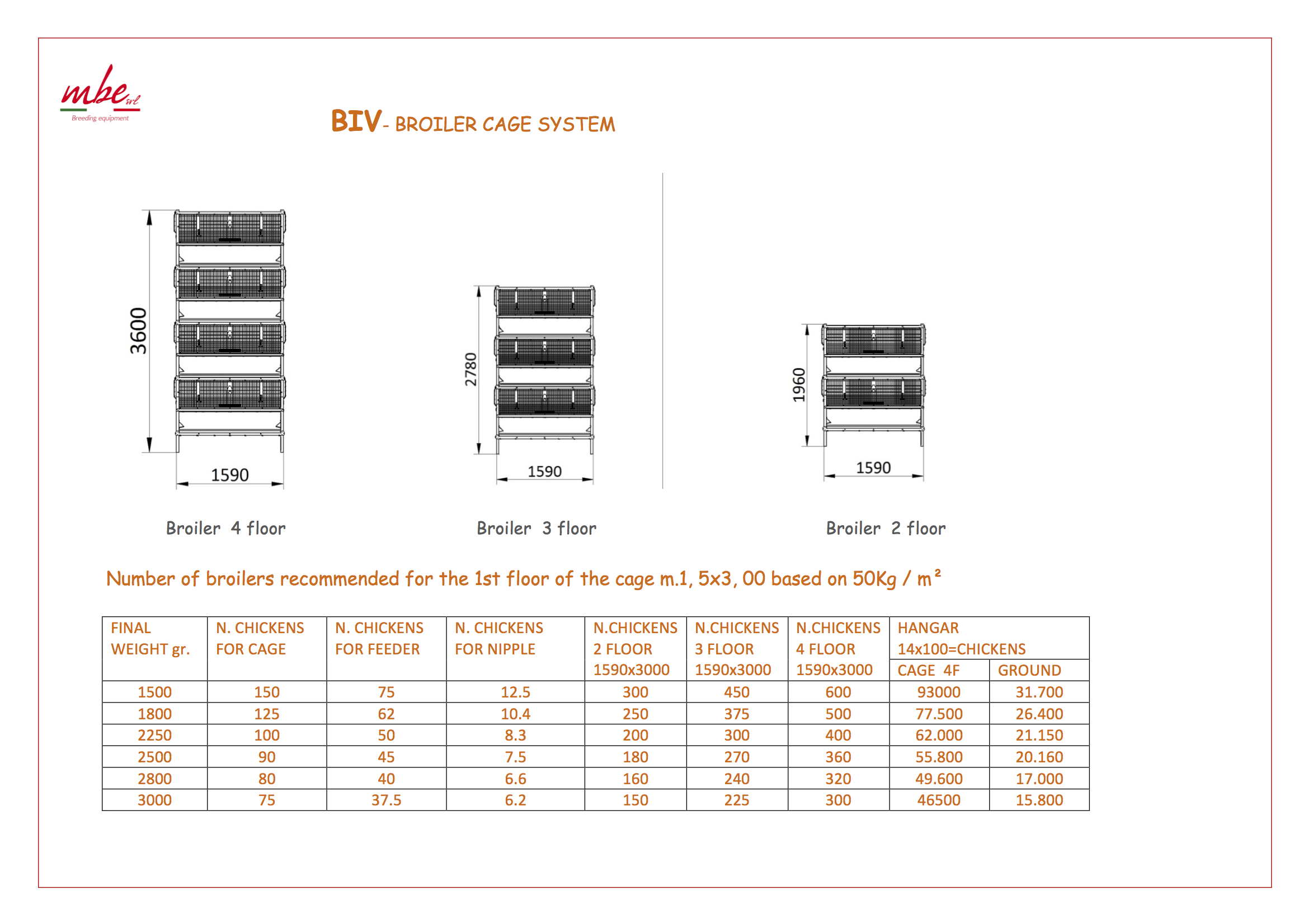

BIV- system colony broiler BIV is the newest belt system cage developed Mbe Breeding Equipment for broiler growing. It has been designed in order to reduce cost and to maximize the profitability, considering the whole lifecycle of the cage, starting from the assembling and then proceeding to management and maintenance. This means: – Two to four times higher stocking capacity, as compared to floor production, with an increased utilization of the surface area and a reduction of energy consumption; – No straw litter, thus better hygienic growing conditions and healthier flocks; also, no additional costs for litter disposal; – Less feed wastage, higher growth rate and better feed conversion rate; Main features BIV: – Very strong frame, with low number of components; – Flexible, soft plastic floor for preventing breast blisters, easy and light to be pulled out because of just 80 cm wide; – Easy and quick accessibility at the flock surface thanks to the sliding doors; – Mesh wire partition and high space inside the bird area provide optimal air exchange throughout the entire barn; – High quality of all the steel parts (high thickness of the zinc coating). Nipple Drinking System Water is supplied by means of two drinking lines with 6 nipples per feed pan in each compartment. The nipple drinkers provide a plentiful supply of water especially during hot summer days. Drip cups prevent water spillage. Feeder and drinker lines can be adjusted in height centrally and can thus be adapted to the size of the birds with minimum effort. Feeding System Feed is supplied by means of automatic feed pans to satisfy the requirements of broilers of any age, from day old chicks to broilers during the last growing phases. After the day-old chicks are moved in and during the first couple of days, the 360° flooding feature provides a high feed level in the pan, without additional labor requirements. As long as the pan sits on the ground, the flooding Feed is supplied by means of automatic feed pans to satisfy the requirements of broilers of any age, from day old chicks to broilers during the last growing phases. As the birds grow, the feeder are raised, thus preventing feed wastage. Cleaning equipmen Polypropylene (PP) manure belts collect the manure beneath the installation. After moving in the day-old chicks, the belts should be cleaned for the first time no later than one week after the moving-in date. In weeks 2 and 3 the manure should be removed every second day and from week 4 onwards the belts should be cleaned daily. This ensures relatively low ammonia content in the house air and prevents fly problems. The end set is galvanized and thus protected against corrosion. The stainless steel manure belt scrapers are equipped with a special U-shaped profile made of polydur which thoroughly cleans the manure belt on every tier. The manure curtains, made of a plastic in front of the manure belt drive, neatly close the system in the area of manure removal. During the growing phase, the lift cross conveyor remains on top, in the parking position, therefore providing free access to the aisles. During the moving out procedure, the manure belt transports the broilers to the end of the system where they are transferred on to the lift cross conveyor. The transfer from cage belt to lift is carried out by means of a comb-type transfer device, in order to facilitate the bird descent and let any residual manure falling onto the manure conveyor. In order to speed-up the moving-out process the same tiers in 2 or 3 rows can be moved-out simultaneously. The lift cross conveyor transports the broilers to the inclined conveyor and then to the catching point

Scheda tecnica